INTRODUCTION

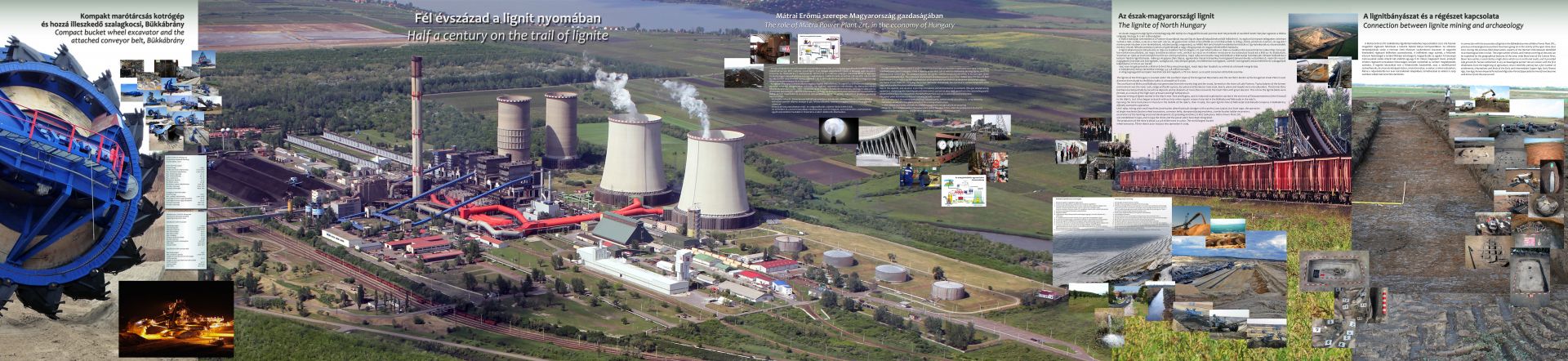

Half a century on the trail of lignite

Half a century on the trail of lignite

The role of Mátra Power Plant Zrt. in the economy of Hungary

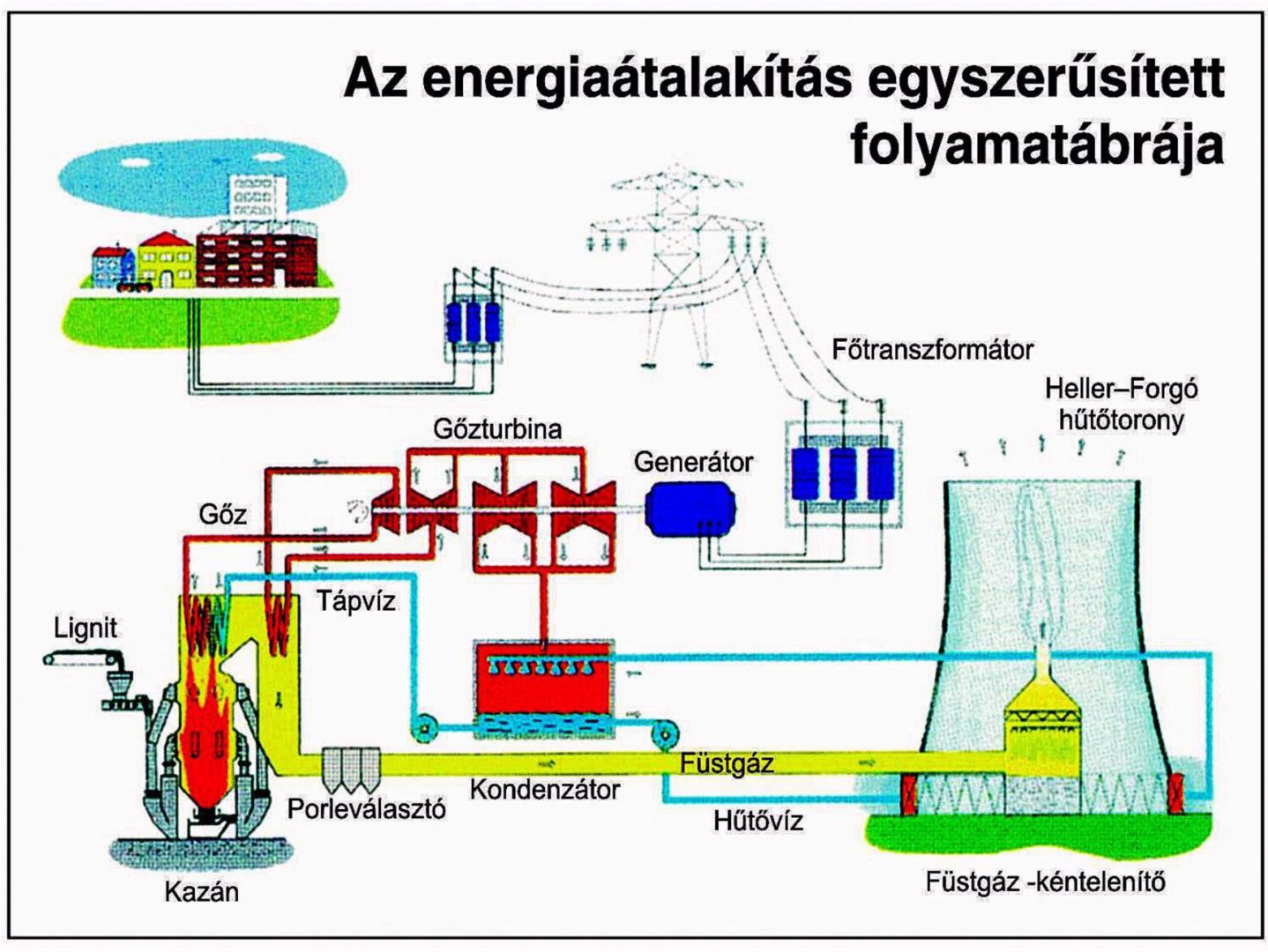

The Mátra Power Plant Zrt., which is under construction since 1965 and has been in operation since 1969, is the largest coal-fired power plant in Hungary. It has a capacity of 950 MW, 93% of which is obtained by burning lignite, and 7 % is obtained from natural gas. The company exploits the lignite, used for producing electricity, in its own open mines (Visonta and Bükkábrány). The estimated total amount of mineral asset is more than 1 billion tons. The two 100 MW coal-fired and 1 x 220 and 2 x 232 MW gas-fired block of the power plant provide 18 % of the power demand of Hungary.

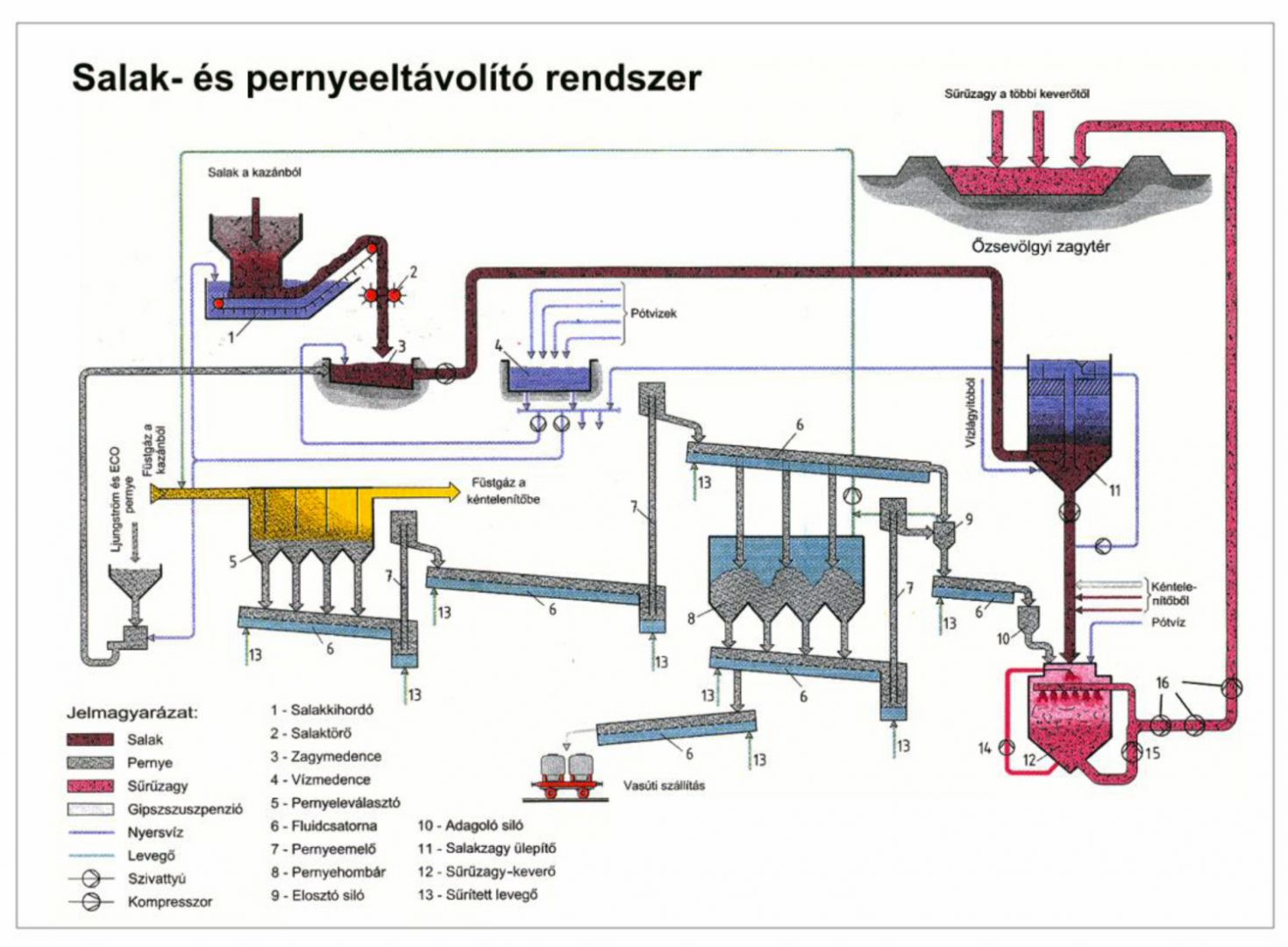

The Mátra Power Plant Zrt., including the former Mátraaljai Szénbányák, has operated in vertical integration since 1993, which unified the plant and the two mines. Due to the capacity- and duration improving innovations and environmental investments (flue-gas desulphurising equipment, technology for removing ash with thick slurry), carried out since 1998, as well as to the outstanding quality and environmental protecting system, the Mátra Power Plant is an up-to-date and eco-friendly plant.

The power plant has several collateral economic benefits as well:

- the by-products of the continuously growing industrial parks, settled nearby are utilized by using electricity and steam, produced in the plant, as well as the existing infrastructure

- on the robbed mine-fields, silviculture, wildlife management and agriculture are occurring

- altogether, 2200 persons work in the power plant and in the open mines, while the employment of external contractors for maintenance, and for other operational works is continuous as well.

The lignite of North Hungary

The lignite of North Hungary is located under the southern slope of the Hungarian Mountains and the northern border of the Hungarian Great Plain in east direction from Aszód to the Bódva Valley in a breadth of 8-12 km.

The coal-basin of Mátra and Bükkalja was generated from the marshy bog and fen wood, formed on the shore of Lake Pannon. Typical plants of the former environment was the reed, rush, sedge and bald-cypress, but pines and deciduous trees (oak, beech, plane and maple) were also abundant. The former flora had been buried partially by lacustrine deposits and by deposits of rivers flown towards the Great Plain with great descent. This is how the lignite fields were formed, as a result of the high layer pressure and high temperature.

Seasonal mining of lignite started in the 1850’s near Tard and Bogács, and its industrial exploitation started in the environs of Rózsaszentmárton (then Fancsal) in the 1890’s, but it has begun to bustle with activity when regular research started in the Bükkalja and Mátraalja in the 1950’s.

Opening the mine took place in Visonta in the middle of the 1960’s, then in 1985, the open lignite mine of Mátraaljai Szénbányák Company in Bükkábrány officially started its operation.

Until 1989, mining with small machines (one-bucket diesel-hydraulic dredger with crawlers) was typical, but from 1990, the operation of larger machines (bucket wheel excavators, conveyor belts, dump-producing machines, crawler-bucket ladder excavators, excavators of the leaching area) and development of spreading-machine (17 km) took place. Mátra Power Plant ZRt. was established in 1992, and in 1993 the mines and the power plant have been integrated. The production of the mine is about 3.5-3.8 million tons in a year. The world largest bucket wheel extractor, PE100-1600/1.5x20 was put into operation in 2009.

Technology of open-cast mining:

- Getting rights and permissions for mining

- Getting territory, buying land suitable for the time of usage

- Preliminary drainage of the area. During which , the water from overburden and interstage water-bearing strata is introduced to the deeper water-bearing formations from where it is lifted to surface by plunger-pump wells installed on the edge of strip-mining area. There it proceeded in loading trough towards the nearby rivers.

- Searching for dangerous features of the ground, neutralization

- Archaeological excavation

- Removal of barren rock, located above the lignite layer (clay and sandy rocks...)

- Cutting of barren rock is accomplished by bucket wheel extractors and one-bucket dredgers

- Barren rock is placed in the dump area with dump producing machines

- The lignite is placed to the conveyor belt by crawler-bucket ladder excavators

- The excavated coal is utilized by the plant and the population after breaking and classifying

- The delivery of coal to the power plant is to be accomplished by railway cars. The reception of lignite takes place in wagon-tipping devices, and then the delivery to the power plant or directly to the power plant blocks occurs on conveyor belts.

- On the robbed mine fields, landscaping, re-cultivating and land utilization occurs

Compact bucket wheel excavator and the attached conveyor belt, Bükkábrány

Manufacturer: SANDVIK Mining and Construction Materials Handling

Beginning of operation: 2009

Specification of the excavator

Operating weight: 1 769 t

Nominal capacity: 6.700 lm³/h

Maximum capacity: 7.300 lm³/h

Max. Block height: 20 m

Max. Block width: 40 m

Max. dredging (?): 1,5 m

Diameter of bucket wheel: 12 m

Number of scoop: 16 db

Capacity of bucket wheel engine: 1100 kW

Belt width: 2000 mm

Crawler width: 4000 mm

Specification of the conveyor belt

Operating weight: 657 t

Max. transport capacity: 7.300 m³/h

Length of Felvevőgém (receiver boom?) from the middle of the machine: 35 m

Length of discharge boom from the middle of the machine: 45 m

Crawler width: 2800 mm

Belt width: 2000 mm

Connection between lignite mining and archaeology

In connection with the excavation of lignite in the Bükkábrány mine of Mátra Power Plant ZRt., previous archaeological excavations have been going on in the vicinity of the open mine since 2007. During the previous field observation, experts of the Herman Ottó Museum identified 16 archaeological sites in total. The large number of sites, and intense covering of the area can be explained by the geographical features of the area: wide flood area of the Csincse River, flown here earlier, is encircled by a high shore which run in north and south, and it provided safe ground for human settlement in any archaeological period. We can reckon with the first inhabitants from the beginning of agriculture, that is Neolithic period, but a fair number of settlements, inhumations and finds of the Early and Intermediate Copper Age, Early Bronze Age, Iron Age, Roman Imperial Period and Migration Period (especially the Avars) have become well-known from the area as well.